FPC flexible circuit board bonding foreign object inspection machine

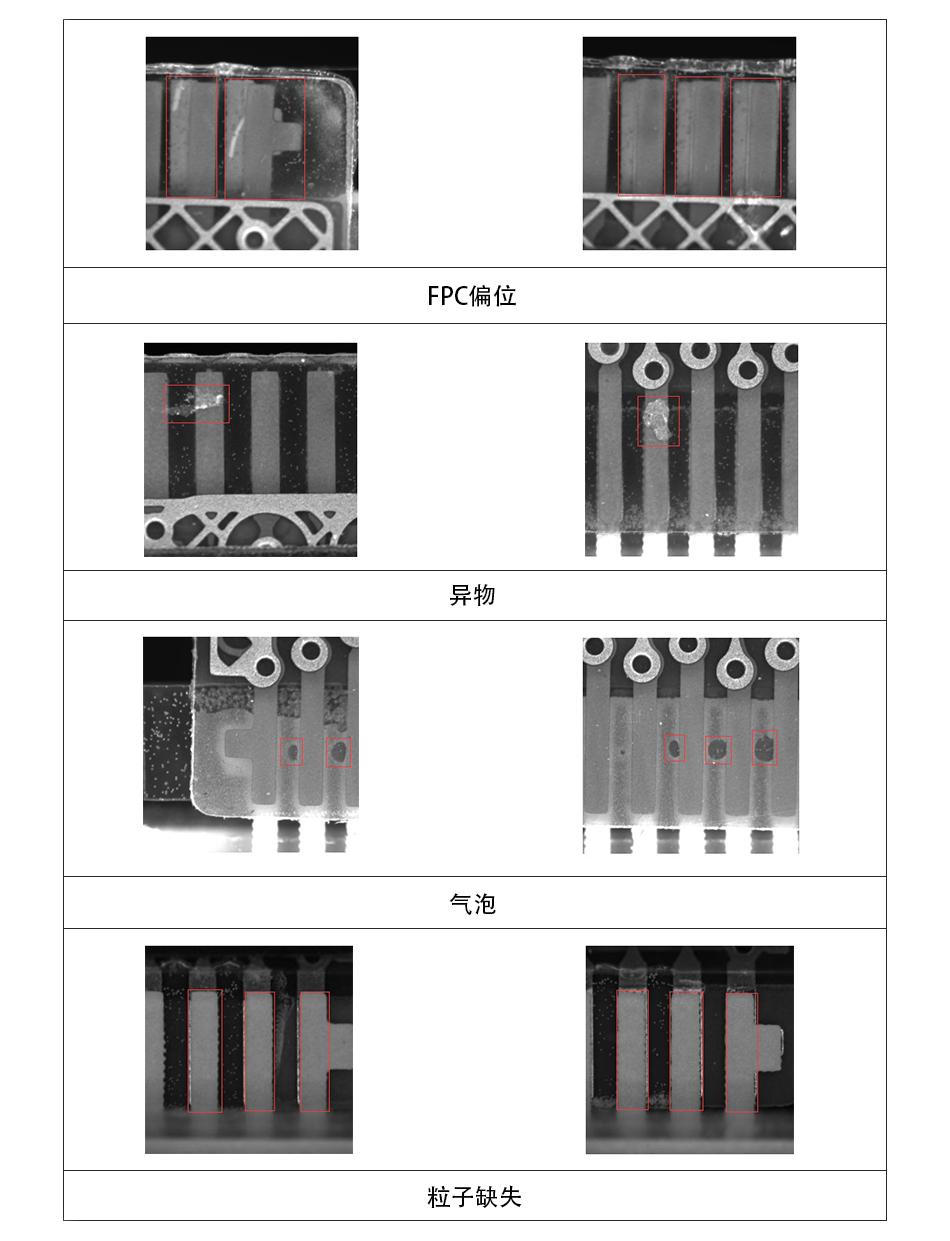

The FPC flexible circuit board bonding foreign object inspection machine is used to detect defects such as FPC misalignment, bubbles, various foreign objects, and missing particles after FPC bonding.

Using an array camera for double-sided shooting, taking defective images, extracting defects through software algorithms, designing different software algorithms for processing and classification according to different defects, and adjusting detection specifications based on algorithm thresholds.

Real time monitoring of the bonding quality of the production line, equipment alarms remind employees to handle batch defects in a timely manner, greatly reducing the occurrence of defective products and preventing them from flowing to the next post.

|

Project |

Performance index |

|

|

Detection system |

Equipment model |

DF1000 |

|

Detection range |

Applicable size: 6-15 inches |

|

|

Detection area |

FPC flexible circuit board bonding area, double-sided inspection |

|

|

Testing items |

FPC misalignment, bubbles, foreign objects, ACF missing glue, overflow glue, whitening, particle missing, etc |

|

|

Pixel accuracy |

0.5 um/pixel |

|

|

Loss inspection rate |

0 DPPM |

|

|

Over inspection rate |

5% |

|

|

*Detection speed |

10 seconds per piece (15.6 inches) |

|

|

Optical system |

Area array camera+Area array camera (multi station combination shooting and imaging) |

|

|

Linear coaxial light source |

||

|

Customized professional optical lenses |

||

|

Positioning system |

Support panoramic positioning |

|

|

Electromechanical system |

Sheet metal frame structure+marble platform to enhance equipment stability and plane reference |

|

|

Using linear motors for transplanting and transporting materials, with high precision and speed |

||

|

The detection platform adopts servo motor+linear module/linear motor/DD motor, which has high precision and rigidity |

||

|

Adopting servo motor and high-precision screw module, used for material code reading, visual positioning calibration and other mechanisms |

||

|

Adopting SMC pneumatic and vacuum system |

||

|

Loading and unloading methods |

CV transmission mode |

|

|

Tray disk storage mode |

||

|

Material box conveying mode |

||

|

Type of transportation |

CV transmission |

|

|

Anti static belt conveyor |

||

|

Four axis/six axis robot handling |

||

|

Multi axis servo motor+linear module/linear motor architecture handling |

||

|

Forklift handling and transportation |

||

|

Flip over |

||

|

Software function |

Otek with proprietary intellectual property rights ® AOI industrial application testing software; |

|

|

Usability: intuitive and user-friendly graphical display interface, intelligent parameter setting function; |

||

|

Humanization: optional alarm function, and the alarm function can be customized (such as the defect rate upper limit alarm function); |

||

|

Quick switching function: Different products can edit and call different recipes; |

||

|

Data security and fast positioning: Abnormal images can be 100% saved and retained: OK saved image+NG thrown material saved image; The image can be zoomed in and out, and the abnormal location of AOI inspection can be identified; Abnormal images should be stored for more than three months with a minimum storage space of 2T; |

||

|

Advanced permission settings: equipped with a window for adjusting the interception rate and setting different permissions; |

||

|

Quick integration with customer information system interface: the detection result data can be saved and uploaded to the CIM system. |

||

|

Detection algorithm |

Processing algorithm |

Otek ® AOI detection algorithm+AI re evaluation system |

|

Symbologies |

Supports reading multiple Vericode codes, corresponding to Normal Type, Normal HD Type Vericode, Outline Type Vericode, and DM Type Vericode |

|

|

Others |

Safety protection |

Safety grating/safety door lock: used for personnel safety protection |

|

FFU: Used for clean equipment to achieve Class 1000 and Class 100 cleanrooms in internal spaces |

||

|

Static electricity: The material in contact with the product is made of anti-static material and equipped with an example air rod to eliminate static electricity |

||

Application areas:

Defect detection covering FPC flexible circuit board bonding process segments such as TP products, mobile phones, PADs, cars, TVs, etc

Defect image: