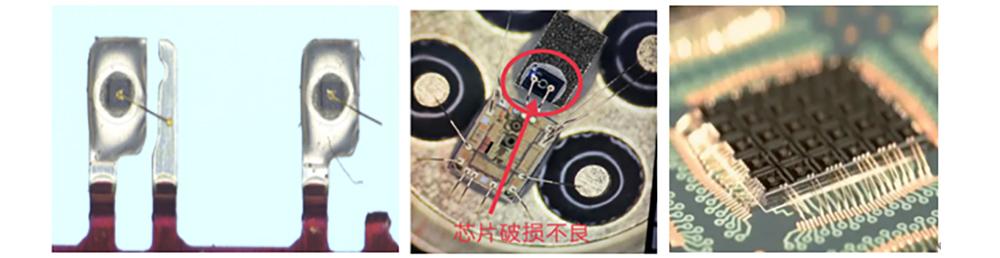

AOI solution for Wire Bonding /Die Bonding adopts the optical system module and core detection algorithm with completely independent intellectual property rights, as well as AI deep learning algorithm, which is suitable for detecting various defects on the grain surface, solder joints, solder lines and frame surface in the process of fixed crystal and wire bonding, and can be used for efficient AOI detection of defects after the fixed crystal Die Bonding and wire bonding in the semiconductor seal testing field, with characteristics of high speed, high precision and high inspection coverage.

It is applicable to the detection of two stations after semiconductor sealing test D/B and W/B.

Using AOI detection algorithm to eliminate background image interference, accurately locate the detection object, focus on detecting various defects in certification, and then use AI deep learning detection algorithm for re evaluation, greatly reducing the misjudgment rate.

Adopting PCL+industrial human-machine interface for equipment operation control and human-machine interaction.

Product type switching+synchronous transmission and saving

Can quickly switch between detection product types;

Support MES networking for synchronizing production data, equipment parameters, and fault shutdown information, with the function of saving cycle numbers.